Contact resistance of power relay and its harm

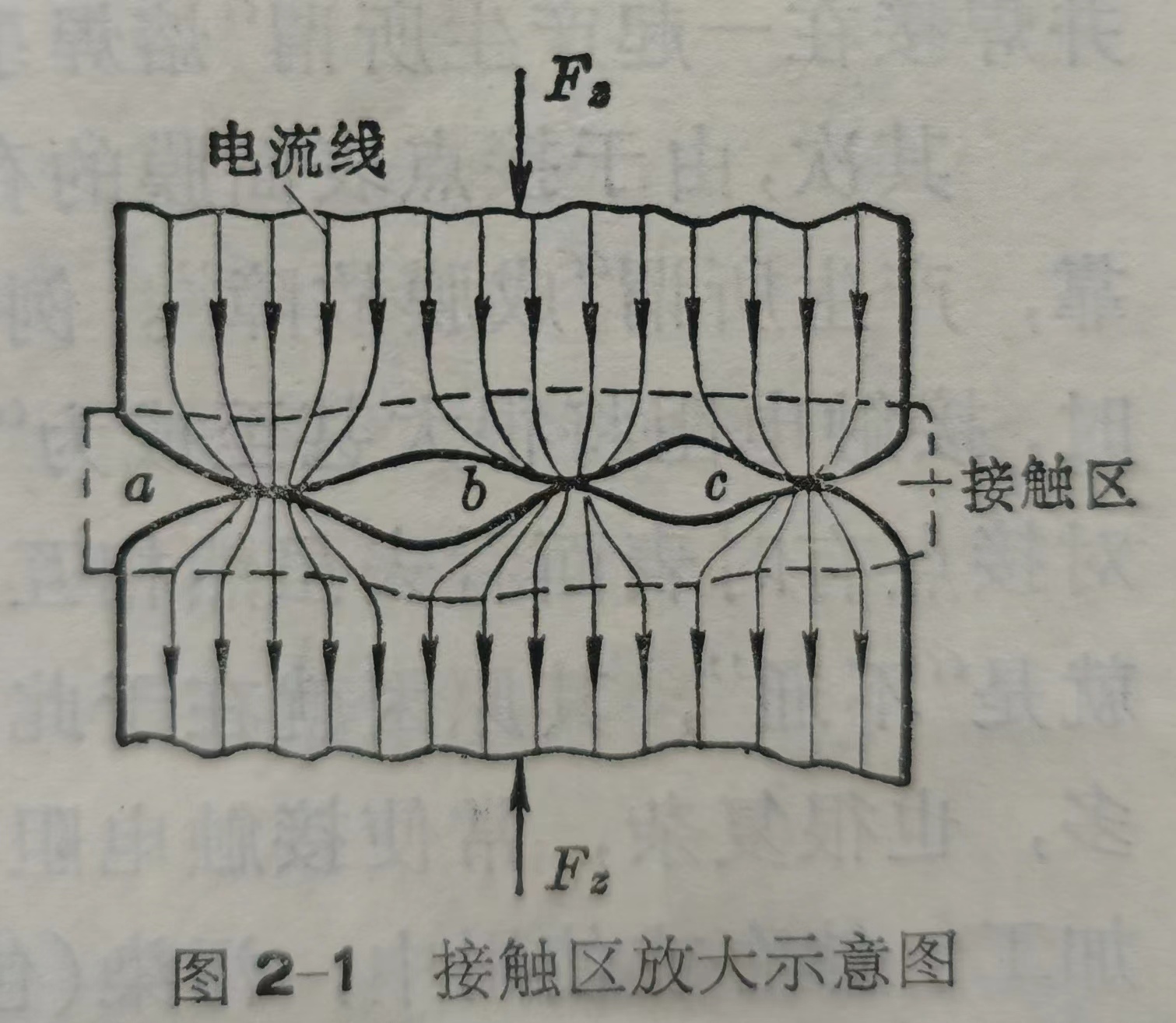

2022-09-13 08:51When the dynamic and static contacts of the power relay work in the closed state, a certain pressure (contact pressure) is always applied to make them close contact with each other, so as to reliably connect the circuit and conduct the current. It is always hoped that the stronger the current conducting ability, the better. It is best to be like a whole piece of metal with the same shape and size. However, this latter hope is only an ideal situation that can not be achieved. In fact, the conductivity of two metals in contact with each other is not as good as that of a whole metal of the same material and geometric size. becauseThe surface of metal materials after processing can never be absolutely flat. Even if the surface looks like a mirror after strict and fine grinding, if you take it to the microscope for observation, you will find that it is also uneven. Therefore, when they are connected to each other.When touching, the actual contact state of the metal can only be a few points. In this way, when current flows through these actual.At the contact point, a serious current contraction will occur (Fig. 2-1), which is equivalent to the reduction of the conductive cross section. Or, take.The conductivity of the part of the area where the dots are in contact with each other (called the contact area) deteriorates, that is, its resistance increases (compared with the whole metal). The resistance increased due to this reason is called "shrinkage resistance".

In addition, there will always be dust, water vapor, fiber, copper and iron particles and other organic substances attached to the joints often exposed in the atmosphere; Inorganic gases such as oxygen and sulfur on the metal surface and in the atmosphere, as well as organic gases volatilized from coil insulation materials, bakelite pieces, flux rosin, etc., will also produce chemical reactions to generate organic or inorganic compounds. The conductivity of these things is very poor, or even non-conductive, which greatly increases the resistance of the contact area. The increased resistance due to this reason is called "surface resistance" or "film resistance" (because a thin film of compound is attached to the contact surface). The sum of the contraction resistance and the film resistance is called the "contact resistance" of the contact (usually represented by the symbol R). It can be seen that the appearance of contact resistance is the difference between the contact and the whole metal of the same material and geometric size, and also the particularity of the contact when it works in the closed state.