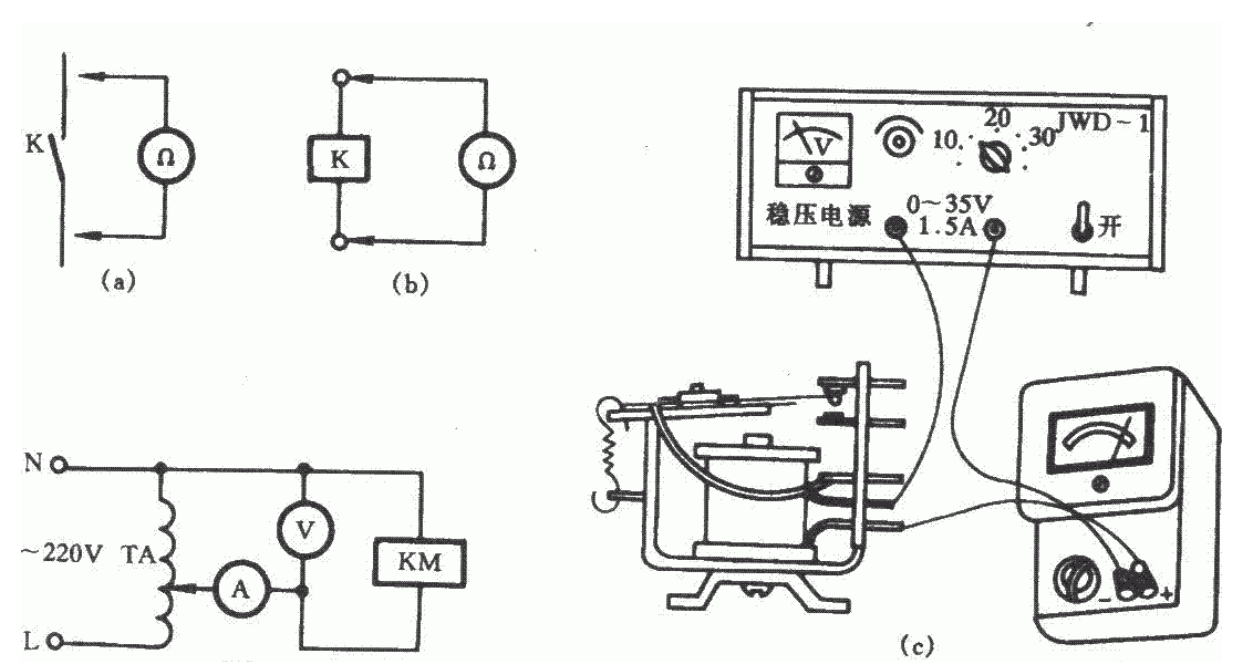

What faults will occur when the contact works in the closed state due to the existence of power relay contact resistance?

2022-09-13 09:33First of all, when current flows through the contact resistance, it will consume a certain amount of power and raise the temperature of the contact, especially the actual contact point. If the current is large, the temperature of the actual contact point may rise to the softening point of the material, resulting in permanent deformation. If the temperature is higher and reaches the melting point of the material, the joints will melt and be welded together, resulting in the so-called "fusion welding accident".

Secondly, due to the existence of facial mask on the contact surface, the operation of the contact will be seriously unreliable, resulting in the so-called "film formation failure". For example, when the film formed on the surface of the contact is very thick, the contact resistance will be very large and even become an "insulator", so that the current cannot be conducted. Sometimes, although a pair of contacts are in contact with each other on the surface, the circuit controlled by them is "disconnected", which is why. In addition, there are many and complex factors affecting the film resistance, which often makes the contact resistance unstable. For example, during the processing, storage or use of power relay contacts, pollution (including chemical action) occurs almost continuously; Dust, fabric fiber, grease, saw iron particles, etc. that are latent on other structural parts will move to the contact surface during the power relay test or work, and the water vapor attached to the contact surface may condense into frost at low temperature; Coil insulation, bakelite parts, flux rosin, etc. will emit a large amount of organic vapor under high temperature, which will continue to pollute the joint. These factors will increase the contact resistance of the contact, and the change is capricious, resulting in serious instability of the contact resistance. This instability not only causes many difficulties to production (such as inconsistent detection data before and after assembly, or even qualified at the beginning of inspection but unqualified after a period of time), but also causes the circuit to switch on and off in use, which seriously affects the normal operation of the circuit.

Are these hazards of contact resistance manifested in any case? no, it isn't. Because the occurrence of this hazard is closely related to the circuit parameters closed by the contact. Different circuit parameters lead to different properties and hazards of contact resistance. For example, when the contact is used to close the circuit with high voltage and current (such as high-power power relay, contactor, etc.), the surface facial mask on the contact can be crushed by high contact pressure or broken down by voltage and burned by current without causing failure. At this time, the main problem of the contact will be the heat generated by the contact resistance (mainly the contraction resistance) when a strong current flows through the contact of the contact. If the design and use are improper, the temperature of the contact will exceed the specified standard or even produce fusion welding. Therefore, How to avoid "overheating" or "fusion welding" of the contact has become the key to this type of power relay contact. In another case, when the contact is used to connect small voltages and currents (such as miniature power relays) Since the current flowing through the contact is very small, the heating of the contact is usually not the main problem. But at this time, since the surface facial mask on the contact will not be broken down or burned, its harmfulness is highlighted, which seriously affects the reliability of this type of power relay. Therefore, how to reduce and stabilize the film resistance has become the most important and prominent problem of this type of power relay contact.